Descriptions

Gear and Bearing Fault Diagnostics and Prognostics

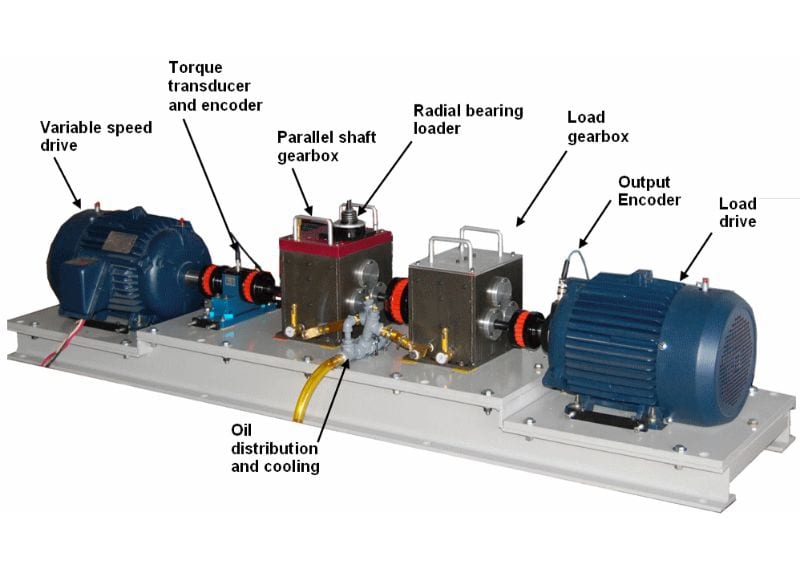

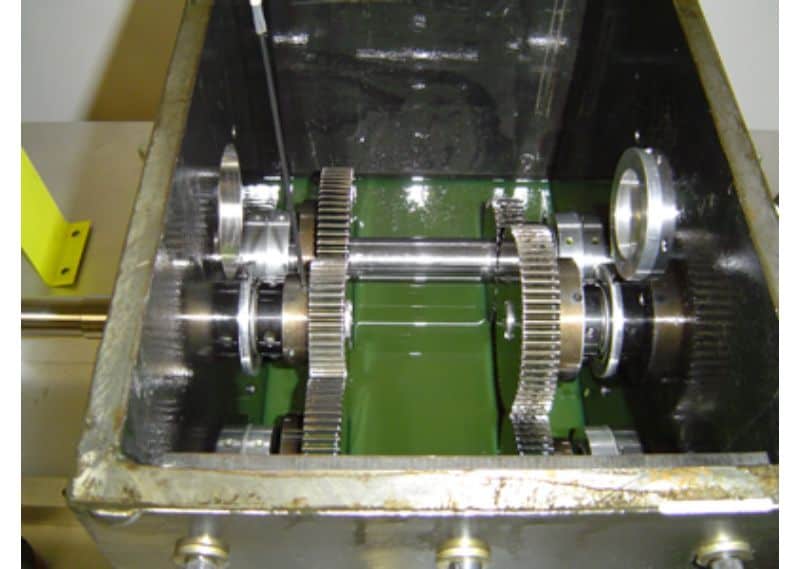

The effect faults like surface wear, crack tooth, chipped tooth and missing tooth can be demonstrated and induced on either spur gears or helical gears. Rolling element bearing faults like inner race, outer race, and ball damage can also be incorporated. Adjustable clearance to study backlash is possible: increasing the amount of backlash is without major consequence, and reducing backlash can result in binding and/or excessive operating temperatures. Gearbox misalignment can also be introduced intentionally in the GPS. Any of these faults can be added to the gearbox one at a time, or simultaneously to study fault interactions. Both torsional and radial loadings can be applied to study damage signature or propagation in gears and/or bearings: the torsional load is applied via a 10 HP variable frequency AC drive with a programmable, user-defined speed profiles; and the radial load is applied to a shaft in the parallel gearbox. With the programmable load drive, load fluctuations can be applied to simulate real life loading conditions.

Features

- One 2-stage oil-lubricated parallel shaft test gearbox up to 6.25 ratio.

- Torsional and radial variable speed loading.

- Gears can slide along the parallel shafts to alter system stiffness and make room for additional devices.

- Parallel shaft gearbox adaptable to spur or helical gears and to rolling element bearings or sleeve bearings.

- Intentionally damaged or worn gearing can be fitted to study the effects on vibration signature.

- Alterable backlash by replacing bearing mounting hubs to provide the desired clearance.

- Modular design makes the introduction of faulted bearing and/or faulted gears an easy task.

- Multiple mounting locations provided for installation of various transducers.

- Develop diagnosis and prognosis techniques and advanced

The GPS is Heavy-Duty and Easily Configurable

The GPS design enables changing gearbox and bearing components quickly and easily. The gearbox is adaptable to install either rolling element bearings or oil-impregnated sleeve bearings with either spur or helical gears. The modular design makes the introduction of faulted bearing and/or faulted gears an easy task.

Transducers and DAQ

The gearbox is designed to accommodate different types of sensors easily. Accelerometers can be installed on the bearing housing to measure the vibrations in all three directions. A torque meter enables precise load measurement. The input and output shafts can be fitted with encoder or tachometer to measure the transmission error or for time synchronize averaging. Other transducers can also be installed per customers’ request. Data acquisition hardware and software are also available from SpectraQuest and ready to do time domain and frequency domain signal analysis.

Packages

High Value Combination Packages

The GPS is available in high value combination packages focusing on both bearings and gears diagnostics.

Package # 1

Basic GPS + Kits for in-depth studies of bearing and gear diagnostics concepts

| Option Kit |

|

PKG1 |

| Parallel gearbox bearing fault kit |

G-BFK-1 |

X |

| Parallel gearbox oil-impregnated sleeve bearing |

G-SBH |

X |

| Defective spur gears |

G-SDG |

X |

| Eccentric Spur Gear |

G-ESG |

X |

| Helical gears set |

G-HG |

X |

| Defective helical gears |

G-HDG |

X |

| PC Motor and Load Control Kit |

G-PCMLK |

X |