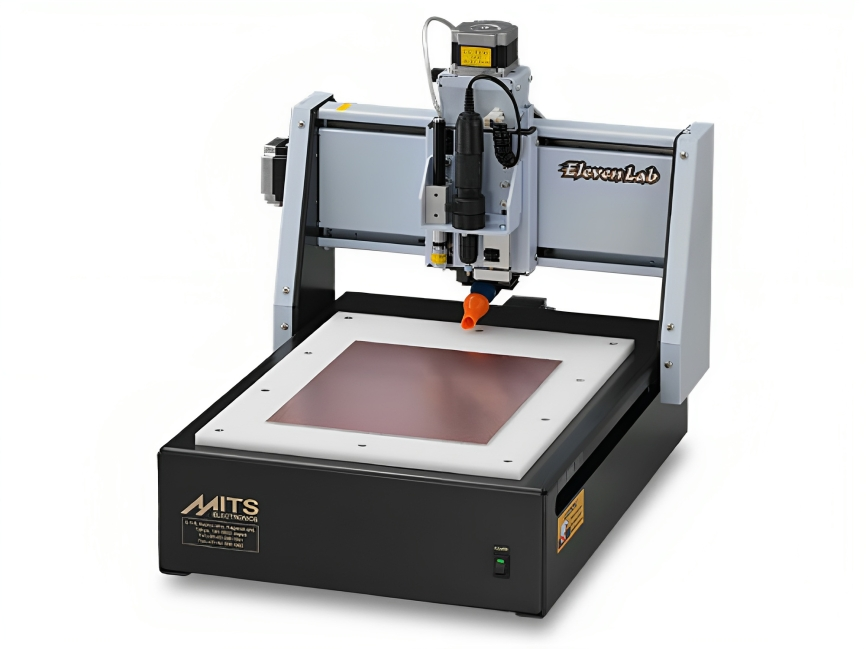

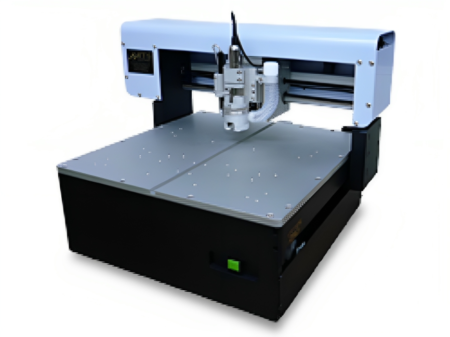

Descriptions

Low-cost, wide range table size, XYZ triple-axes control, high resolution, standard camera monitoring system

Suitable for processing normal PCB.

Spindle Speed

41,000 rpm

Manual Tool Change

Tool change is done manually by the user. Uses an easy-to-use lever to remove and insert the tools.

Tool change can be done without any complicated action such as thread fastening.

Cabinet (requires assembly) is available as an optional item

Well designed and easy to perform maintenance.

Standard camera monitoring system

Magnify the surface of the board and display on a monitor. You can easily adjust the right position while viewing display.

(Maximum useful magnification depends on the size of the screen)

Fiducial positioning camera

The Color micro-scope can be installed beside the head assembly of the PCB prototyping Machines.

Easy plug & play with USB connection presents 30x / 60x display of the surface of the board.

30 x

This is the useful option for the alignment

Microscope Features

30x (15″ monitor)

- 1,300,000 pixels CMOS

- 640 x 480 resolution (On Design View)

- super luminosity LED x 8 (modulate light)

- USB interface

*The right side 40 mm of milling area is out of range of view field.

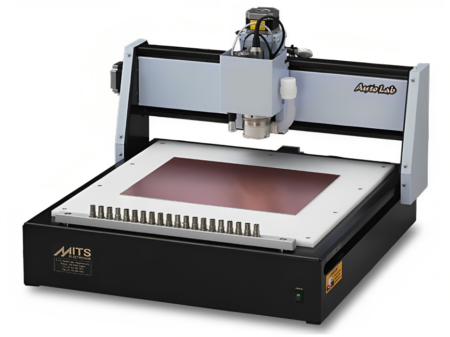

Vacuum table

The vacuum table option employs the porous resin which holds tightly in the whole area

of the surface. This stabilizes the substrate tightly without causing twisting or warpage.