Descriptions

The AdvaPIX TPX3 can be used in a variety of applications, such as energy resolved radiography (X-rays, neutrons, ions), particle tracking, time-of-flight imaging, Compton camera and many others. The sensors can be adapted for neutron imaging, by deposition of the converter layer (6LiF). Recording individual hits together with advanced data processing allows imaging at super spatial resolution. It can reach in some applications units of microns (X-rays) or even sub-micrometric level (ions).

Compared to the older Timepix chip, the Timepix3 detector offers imaging with 6x better time resolution, 2x better energy resolution, 2x lower minimum energy threshold, zero dead time, and 10x faster data transfer.

Applications

Non-Destructive Testing

ADVACAM’s X-ray digital radiography imaging detectors are an ideal solution for many Non-Destructive Testing (NDT) applications. The photon counting detectors provide improved sensitivity, spatial resolution, contrast and signal-to-noise ratio. The broad range of detectable X-ray energy starting from 5 keV up to hundreds of keV or even MeV let the detectors capture from very light composite materials up to thick welded parts.

In addition, the energy discrimination helps suppress the scattered radiation and improving the contrast of measured images. NDT specialists and service providing companies can extend the portfolio of customers by those whose products could not be inspected by X-ray radiography in the past. Our new X-ray imaging technologies are useful for inspecting composite materials in the aerospace industry.

Mining and Geology

Material discriminating X-ray imaging of ore

The energy sensitive photon counting detectors can help in this area thanks to the option of material identification in images. Drill cores from exploration bore holes can be now analysed in-situ identifying different minerals and providing immediate feedback for further exploration.

Online monitoring of technological processes during mineral processing is another very important area where X-ray material resolved imaging plays an important role. It helps to increase effectivity of processing and reduce energy consumption leading not only to reduced costs, but also to lower environmental effects.

X-ray Diffraction

X-ray diffraction is analytical method based on inspection of crystalline structure of samples used in applications, such as metallurgy, mineralogy, powders, pigments, polymers, surface layers and strain mapping. The traditional X-ray diffraction uses monochromatic X-rays which make the apparatus large and slow.

ADVACAM’s spectral detectors based on Timepix3 chip with high resolution makes the diffraction system fast and compact. The sample analysis can be performed 100 times faster compared to the conventional systems. Due to fast speed of the analysis large areas of the sample can be analysed by scanning.

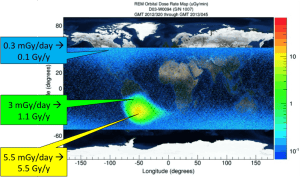

Charge Particle Tracking and Space Dosimetry

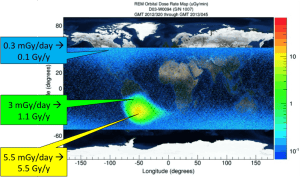

Spatial-correlated radiation dose on flight path of ISS mapped on Earth at 400 km altitude. Courtesy of NASA.

NASA together with IEAP CTU and University of Houston has used MiniPIX type of cameras in the International Space Station (ISS) to track charged particles and measure their energy deposited to study and surveil the radiation exposure that astronauts face in space. It is possible to measure accurately the dose in the complex environment of space where the radiation environment is completely different than on surface of the Earth.

NASA is flying the ADVACAM’s ModuPIX Tracker in the International Space Station since March 2017. The goal of the project is to demonstrate the capability to determine the directional characteristics of charged particle energy spectra in space.

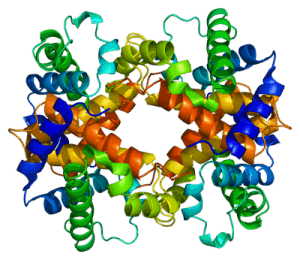

Crystallography

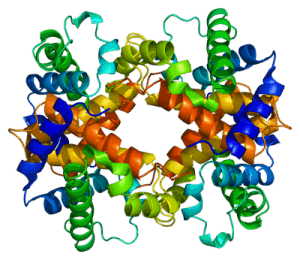

Reconstructed image of human hemoglobin (HBA1) protein.

X-ray crystallography is used to study detailed atomic or molecular structure of the sample at synchrotrons. High frame rate AdvaPIX QUAD is specially designed for combined Wide Angle X-ray Scattering (WAXS) and Small Angle X-ray Scattering (SAXS). The open space in the center of the camera allows the X-ray beam pass through the camera eliminating complete the need to use a beam stop in front of the camera.

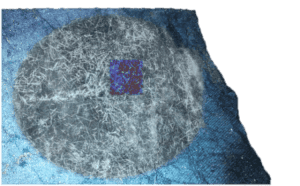

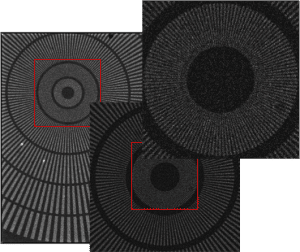

High resolution neutron imaging

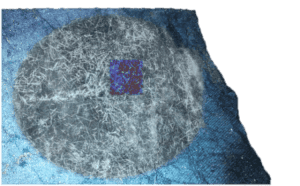

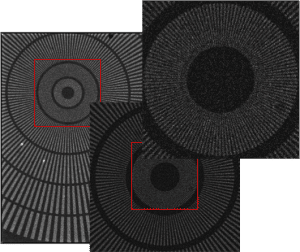

Siemens start imaged with cold neutrons in high resolution of 2.5 um and image size of 2560×2560 pixels. Courtesy if IEAP CTU.

AdvaPIX camera with detector coated by thin film of LiF is able to achieve ultra-high spatial resolution for thermal neutron imaging. The camera offers sigma of Point-Spread-Function spatial resolution of up to 2.5 µm. The camera’s field of view is 14×14 mm that gives at the maximum resolution 6.5 MPix.

The camera is equipped with a Silicon sensor with neutron conversion layer of 6LiF. Thermal neutrons are captured by 6Li that produces Alpha particles and tritons. These heavy charged particles are then detected in the Silicon sensor. The ultra-high spatial resolution is achieved by processing of individual neutron hits while taking into account also charge collection in the sensor. All this advanced processing is implemented in the camera software, which is simple to use.