Applications

Non-Destructive Testing

ADVACAM’s X-ray digital radiography imaging detectors are an ideal solution for many Non-Destructive Testing (NDT) applications. The photon counting detectors provide improved sensitivity, spatial resolution, contrast and signal-to-noise ratio. The broad range of detectable X-ray energy starting from 5 keV up to hundreds of keV or even MeV let the detectors capture from very light composite materials up to thick welded parts.

In addition, the energy discrimination helps suppress the scattered radiation and improving the contrast of measured images. NDT specialists and service providing companies can extend the portfolio of customers by those whose products could not be inspected by X-ray radiography in the past. Our new X-ray imaging technologies are useful for inspecting composite materials in the aerospace industry.

Mining and Geology

Material discriminating X-ray imaging of ore

The energy sensitive photon counting detectors can help in this area thanks to the option of material identification in images. Drill cores from exploration bore holes can be now analysed in-situ identifying different minerals and providing immediate feedback for further exploration.

Online monitoring of technological processes during mineral processing is another very important area where X-ray material resolved imaging plays an important role. It helps to increase effectivity of processing and reduce energy consumption leading not only to reduced costs, but also to lower environmental effects.

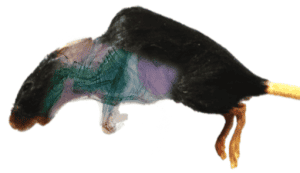

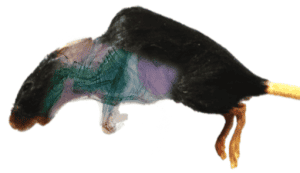

Spectral Imaging Of A Mouse

Cancer research, biomechanics, and drug testing are just a few examples of where X-ray imaging contributes to research in biology and medicine. New photon counting detectors represent a serious advancement for these applications, compared to previously used synchrotrons. The energy sensitivity of modern cameras opens better possibilities to identify individual types of tissue. That has important consequences in various industries, for example cancer research, where the tumour tissue can be better distinguished from the healthy one.

Spectral Radiography

Material discriminating spectral imaging of a mouse. Colours represent different tissue types.

The high sensitivity of photon counting detectors to low energy photons makes them useful for imaging low X-ray attenuating objects (i.e. light objects, such as tissue.) Thus, these detectors are ideal for bio-related applications. The low X-ray energy sensitivity (starting from ~3 keV) together with the high dynamic range reveals features in samples that remain hidden to other types of X-ray imaging detectors.

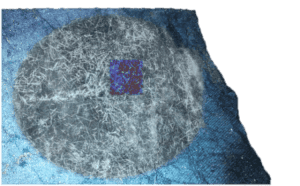

Spectral Computed Tomography

Spectral computed tomography slices where each colour represents a tissue type.

The spectral radiography can be extended to 3D by means of computed tomography. This makes it possible to recognize different types of tissue in real form. Again, this level of information can be incredibly helpful for cancer treatment research, as it gives better data for irradiation planning.

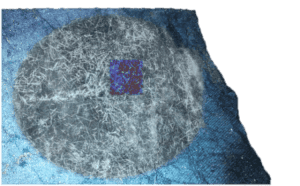

Authentication of art

Study and characterization of art pieces, namely paintings, using X-ray imaging is becoming an increasingly important area. It is useful for galleries, museums and collectors to improve conservation and preservation methods. It is important for art buyers to reliably authenticate the works. The advanced X-ray imaging techniques provide detailed data for insurance companies to assess risks involved in transportation of art.

The spectral imaging capability of Advacam’s detectors enables identification of different pigments based on their spectral responses. A “colour” X-ray image is then created where the colours are associated to different pigments identified in the painting. The recognition of pigments even in invisible lower layers can serve as an important clue in the process of art authentication.

Advacam’s spin-off company InsightArt

Advacam has transferred the art inspection offering to its spin-off company InsightArt. The goal of the company is to be one-stop shop for the art collectors, auctions and galleries. The company analysis paintings and other pieces of art using advanced X-ray imaging techniques combined with the conventional ones. The combination of the techniques allows unprecedented technique for studying art and identification of different types of materials and pigments in the images.