Applications

Non-Destructive Testing

ADVACAM’s X-ray digital radiography imaging detectors are an ideal solution for many Non-Destructive Testing (NDT) applications. The photon counting detectors provide improved sensitivity, spatial resolution, contrast and signal-to-noise ratio. The broad range of detectable X-ray energy starting from 5 keV up to hundreds of keV or even MeV let the detectors capture from very light composite materials up to thick welded parts.

In addition, the energy discrimination helps suppress the scattered radiation and improving the contrast of measured images. NDT specialists and service providing companies can extend the portfolio of customers by those whose products could not be inspected by X-ray radiography in the past. Our new X-ray imaging technologies are useful for inspecting composite materials in the aerospace industry.

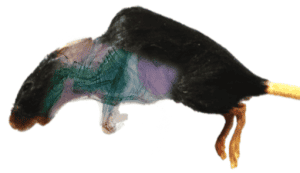

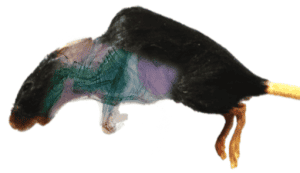

Spectral Imaging Of A Mouse

Cancer research, biomechanics, and drug testing are just a few examples of where X-ray imaging contributes to research in biology and medicine. New photon counting detectors represent a serious advancement for these applications, compared to previously used synchrotrons. The energy sensitivity of modern cameras opens better possibilities to identify individual types of tissue. That has important consequences in various industries, for example cancer research, where the tumour tissue can be better distinguished from the healthy one.

Spectral Radiography

Material discriminating spectral imaging of a mouse. Colours represent different tissue types.

The high sensitivity of photon counting detectors to low energy photons makes them useful for imaging low X-ray attenuating objects (i.e. light objects, such as tissue.) Thus, these detectors are ideal for bio-related applications. The low X-ray energy sensitivity (starting from ~3 keV) together with the high dynamic range reveals features in samples that remain hidden to other types of X-ray imaging detectors.

Spectral Computed Tomography

Spectral computed tomography slices where each colour represents a tissue type.

The spectral radiography can be extended to 3D by means of computed tomography. This makes it possible to recognize different types of tissue in real form. Again, this level of information can be incredibly helpful for cancer treatment research, as it gives better data for irradiation planning.

X-ray diffraction

X-ray diffraction is analytical method based on inspection of crystalline structure of samples used in applications, such as metallurgy, mineralogy, powders, pigments, polymers, surface layers and strain mapping. The traditional X-ray diffraction uses monochromatic X-rays which make the apparatus large and slow.

ADVACAM’s spectral detectors based on Timepix3 chip with high resolution makes the diffraction system fast and compact. The sample analysis can be performed 100 times faster compared to the conventional systems. Due to fast speed of the analysis large areas of the sample can be analysed by scanning.

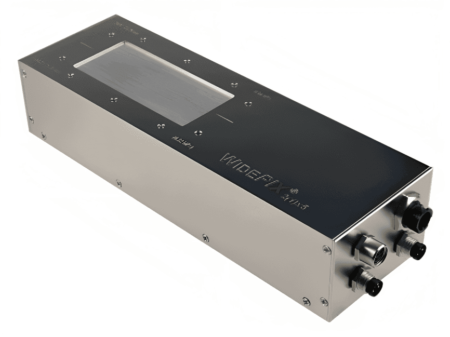

Polychromatic X-ray diffraction

Polychromatic X-ray diffraction operation principle and comparison between standard and spectral detector.

The polychromatic X-ray beam (instead of monochromatic) can be used with ADVACAM’s energy dispersive detectors. Polychromatic X-ray diffraction system is compact and less complex than the one with monochromatic X-ray that require mechanically moving parts. The high resolution spectral detector can be placed close to the sample covering large solid angle.

Example of experimental minituarized polyhromatic X-ray diffraction setup with AdvaPIX TPX3 detector.

The high intensity of the polychromatic X-ray beam enables high speed of data accumulation. Broad energy range from 3 to 150 keV can be covered with the polychromatic X-ray tube. The high X-ray energies allow transmission and diffraction study of highly absorbing samples, such as stainless steel, heavy metals and minerals. The X-ray diffraction at high energies has only been possible with large synchrotron accelerators so far. ADVACAM’s spectral detectors enables user to perform synchrotron measurements at their desk.

X-ray diffraction of silicon powder using AdvaPIX TPX3 detector in distance of 25 mm with polychromatic X-ray beam of 0.5 x 0.5 mm at 80 kVp.

The example on the right shows a polychromatic diffraction images of silicon powder using a standard and spectral detector AdvaPIX TPX3. The standard detector mixes all the energies and image is useless in identifying diffractograms in a stationary diffraction setup. The spectral detector is able to observe the rings clearly and identify multiple diffractograms. By recalculating and summing the diffractograms (1 keV energy intervals) one is able to visualise the lattice constant of the material shown on the right for the Si powder.