Features

Typical Applications

- Thickness gauging on rough or corroded surfaces

- For applications up to 932°F (500°C)

- Thickness gauging on pitted, curved, and irregular surfaces

#2 Flat Bottom Hole at 0.5″

RF Waveform Image (Left) and Frequency Spectrum (Right)

Backwall Signal from 1″ Steel Block

Thermal-Cycle Testing

400°F Heat Up at 932°

At 932°F continuous surface contact temp, it takes over 9 minutes for the sensitive solder joints within the transducer to get to 400°F.

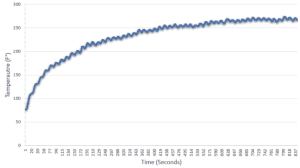

33% Duty Cycle

This chart shows a 33% duty cycle at 5 seconds on and 10 seconds off. The DHT-400 plateaus at ~270°F which keeps the sensitive elements rom ever reaching 400°F. At a 50% duty cycle of 10 seconds, the DHT-400’s sensitive elements never get to 400°F.