Features

Typical Applications

- Carbon Composite Inspection

- Irregular Shapes & Surfaces

Series

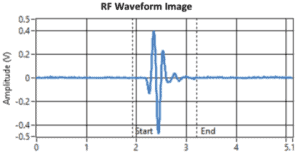

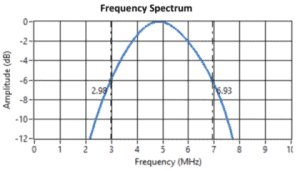

*C Series – Composite (Piezocomposite) series of transducers have superior sensitivity and penetration, especially in highly-attenuative materials. C Series have both higher resolution, sensitivity, and have wide bandwidth (60-120% at -6db) due to the lower acoustic impedance of the material. They couple more efficiently into plastic wedges, delay lines, and water.