Features

AlphaCell predicts the vibro-acoustic response of multi-layer systems to various sound excitations

- Easy & fast simulations

- Listen to sound package efficiency

- Complete set of material models

- Broad application material library

- Various imports / exports

- Reactive and skilled support

Other key features include:

- Intuitive interface

- Listening of solution efficiency

- Plane and curved geometries

- Thermal properties including bridges

- Multiple studs in series

- Generalised equivalent plate & porous models

- Imperfect interfaces

- Corrugated & ribbed plates

- Multiple fluids including water

- Compressed fibrous model

- Extended material library

- Fully scriptable

- Export of material cards and FE model

Principle

By means of a simple “Drag&Drop” functionality, the single layers of the multi-layer system are assembled one by one. Subsequently, the excitation conditions in terms of airborne sound and structure-borne sound as well as the specific parametrized calculation models for the different materials can be chosen independently.

All material parameters required for calculating the vibro-acoustic properties can be assigned from a material database. By modifying the different geometrical and material-specific parameters, the vibro-acoustic behaviour of different multi-layer systems can be compared and optimized very efficiently and effectively.

Calculations

Calculated Indicators

Amongst others, the following indicators can be computed:

- Sound absorption coefficient, sound reflection coefficient, surface impedance, dynamic mass density, dynamic bulk modulus

- Sound transmission loss

- Impact sound level, attenuation of impact sound level

- Quadratic velocities at front and rear side of respective building element (sending and receiving room)

- Incident and radiated sound power (sending and receiving room)

- Associated unique indicators (single-number values according to ISO 10140 series)

Excitation Conditions

The vibro-acoustics software enables to select from various excitation conditions. These include:

- Single plane sound wave incident from an arbitrary angle

- Diffuse sound field (statistical sound incidence)

- One- and two-dimensional modal sound field

- Single mechanical force

- Impact sound of tapping machine

- Rain-on-the-roof excitation

- Turbulent boundary layer

AlphaCell – sound absorption coefficient of open-cell foam as a function of frequency – comparison of measurement result with calculation results by means of two different absorber models

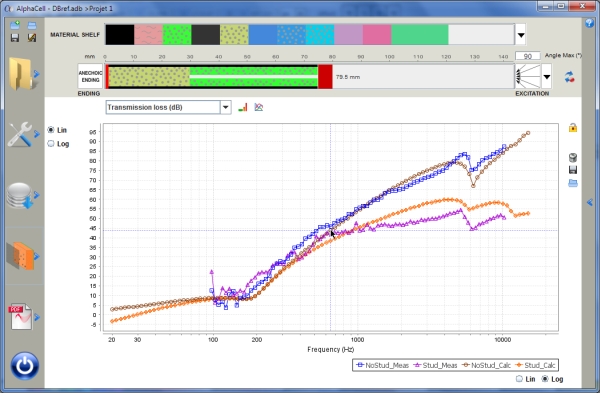

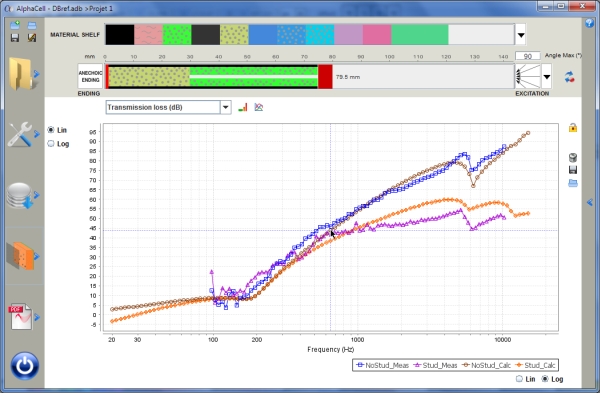

Transmission loss of double-layer wall setup (steel sheet-porous absorber-steel sheet) with and without studs – Comparison of calculation results of software AlphaCell with results of measurements in the test setup (see Validation Booklet)

Models

Available Calculation Models

A large number of calculation models are provided by the vibro-acoustics software, e. g.:

- Porous materials

- Fibrous: Delany-Bazley, Delany-Bazley-Miki, Attenborough

- Granular: Horoshenkov-Pore Size Distribution, Hamet

- Fibrous, cellular: JCA, JCAL, JCAPL, Miki, Wilson

- Imported measured data

- Perforated plates/fabrics

- circular, square, slit perforated plates

- screens, woven/non-woven fabrics

- Solid materials

- Elastic isotropic

- Visco-elastic isotropic: frequency-dependent values of Young’s modulus, Poisson ratio and damping loss factor

- Septum

- Impervious screen

- Limp and rigid bodies

- Orthotropic 3D

- Transverse isotropic

- Thin orthotropic plate

- Heterogeneous materials

- Double porosity materials, porous composites

- Stud for double leaf partitions (point or line connection)

- Porous media with inner resonators

The majority of calculation models has been extensively validated by comparing calulation results of vibroacoustic characteristic values of the software AlphaCell with results of measurements in the test setup or numerical simulations.

Specimens of materials with open porosity

Evaluation of transmission loss of multi-layer system (steel sheet-metal foam-steel sheet)