Descriptions

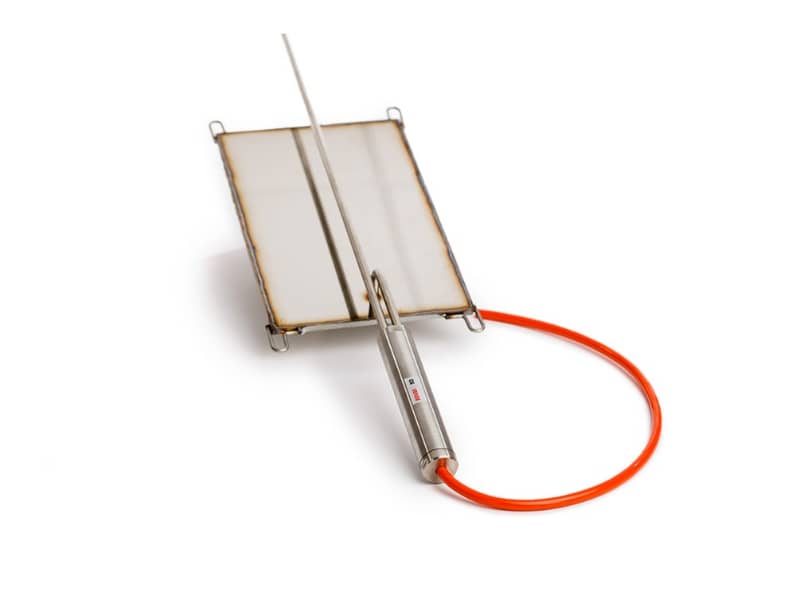

The cells are constructed from two stainless steel plates welded around their periphery with the narrow gap between the plates filled with hydraulic fluid.

As the stress increases within shotcrete or concrete the fluid pressure within the cell rises as the plates are squeezed together.

A length of stainless steel tube connects the plates to a pressure transducer (VWDT 5000 or SGT 3000) that converts the pressure to an electrical signal which can be read directly with a MP12 readout or data logged.

NATM cells installed in concrete expand with increasing temperature as the concrete or shotcrete cures. After cooling the cell will contract leaving a gap between it and the concrete so that the stresses are prevented from reaching the well. In order to continue to monitor the stresses the cell can be re-pressurised using the attached pinch tube to re-expand the cell so that it once again comes in contact with the concrete surface.