Descriptions

Is it so special to be able to use 0.1mm RF milling bits?

Yes, indeed.

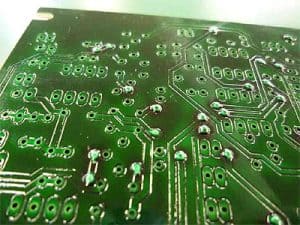

To ensure desirable RF characteristics, it is necessary to use special RF milling bits to cut RF boards. This type of tools have cylindrical tip as shown in the picture shown below. As you can, 0.1mm RF milling tool has very thin cylindrical tip, and is very flrangible compared to a standard milling bit.

For typical board making, milling bits with pointed conical tip (“typical bit” shown below) are commonly used. This type of cutter is useful for making standard boards quickly in quantity because it is thick and strong. However, it is not desirable to cut 0.1mm patterns for RF boards with conical tipped bits because the channel cross section becomes trapezoidal.

In order to use an 0.1mm RF milling bit, the machine has to minimize the vibration of its mechanism and the spindle motor and runout.

In the words…

If a prototyping machine is capable of using 0.1mm RF milling bits, that machine must be high performance.

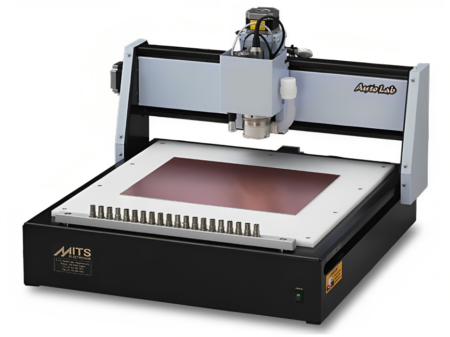

FP-21T is designed for highly right machine construction and has a high performance spindle motor with very low runout (within 20µm). Furthermore, this motor uses ceramic bearings for longer service life.

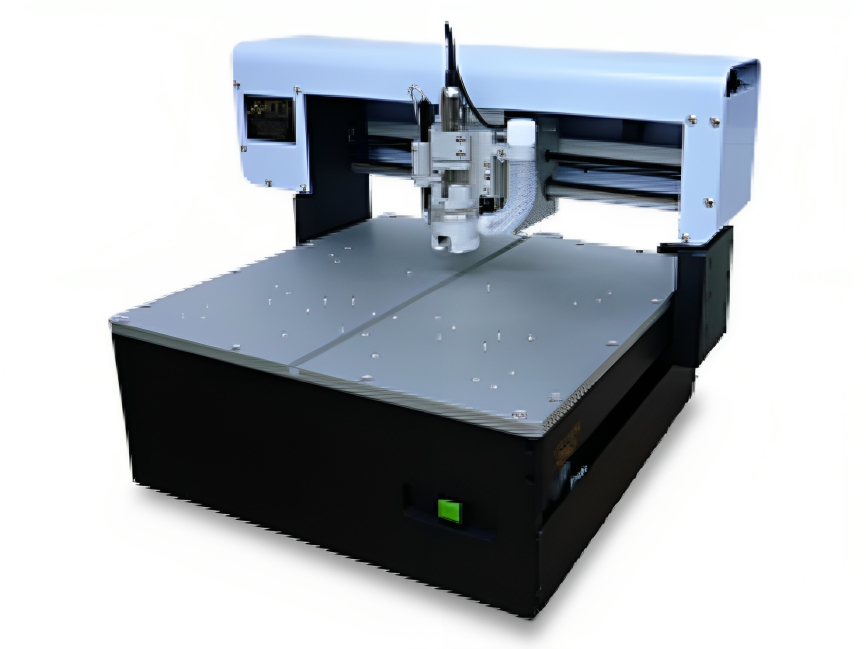

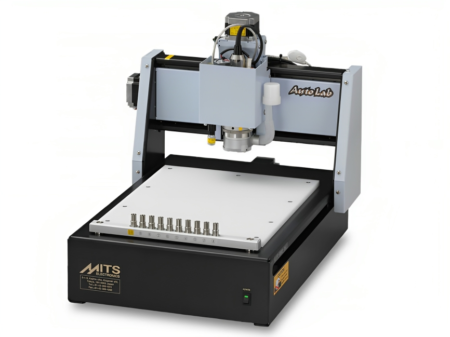

FP-21T model 60

We recommended FP-21T model 60 for those who are interested in processing high load material in quantity or for long hours. Thanks to its spindle motor construction, model 60 is better suited for processing heavy load materials compared to model 40/U.

You can process many materials besides cupper substrate board

FP-21T is compatible with the various types of processing besides the normal substrate board.

The Z axis stroke is large enough and numerical controllable, so it is suitable for the surface processing of the thick material.

Additionally, the air pressure model (FP-21T HP) can process the material in non-contact way, you can process the soft materials without scratching the surface.

Application example of FP-21T user

- Besides the cupper substrate board, plastic resin, aluminum, free-machining ceramic

- Surface processing of the thick material

- Supplementary processing

- For routing processing

- Large size antennae board processing (custom-made)

Fiducial positioning camera

Zoom the surface board at 30 times magnification, and you can align the positioning easily and accurately. It is also effective for the supplemental processing of the finished board.

Vacuum table

The porous plastic resin aspirate the substrate board evenly. This equipment can fix the thin material or film without misalignment or warping.

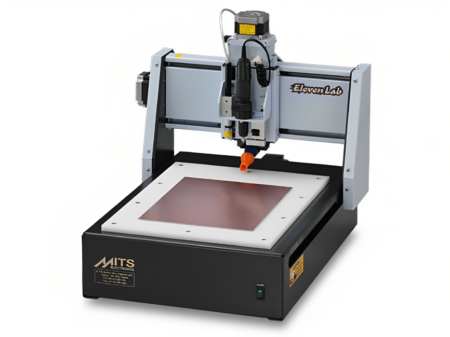

Non-Contact Milling Head

As the board is pressured by air pressure, it leaves no undersirable traces on the board surface.

Suitable for milling the soft substrate board such as teflon circuit board.

(By attaching the non-contact milling head to the FP-21T, “HP” will added to the model name; FP-21THP. )

Non-Contact Board Making & Contact Board Making

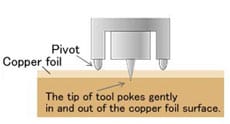

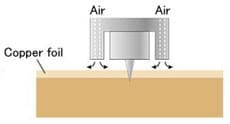

When making boards with fine patterns, we usually adopt the incremental milling method in which the material board is held down and the tool tip is made to stick out accurately from the very point where the board is being held down. For holding down the material boards, there are two methods called the contact method and the non-contact method.

Contact Board Making System

This system leaves the thin trace of pivot touch on the surface of copper foil.

(But this pivot does not leave any scratch.)

Non-Contact Board Making System

As the jet of air pushes down the board without touching, this system leaves no trace on the copper foil. Therefore, this system is suitable for the processing of thin or soft board materials. However, additionally you have to have an air compressor.