Features

Typical Applications

- Flat Plates

- Bars & Pipes

- Thick-Section Parts

- Tanks

- Objects with simple and non-complex geometries

Key Benefits

- Smaller diameter allows for inspection of pipes, bars, and tubes

- Abrasion-resistant wear plates for extended service life

- Effective in small-flaw detection

Series

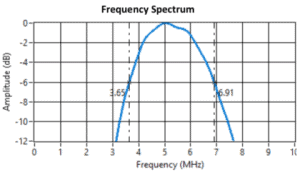

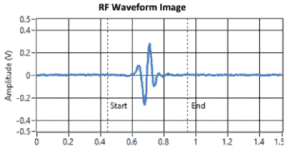

*GP Series – General Purpose Series of transducers are recommended for most applications and have a good trade-off between sensitivity and resolution. They have a medium frequency bandwidth of 40-65% at -6db but with more ring-down cycles in the waveform.

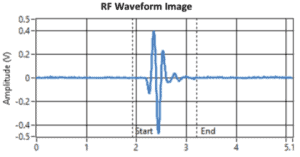

*HR Series – High Resolution series of transducers are highly damped and recommended for applications where enhanced axial and near-surface resolution are more important. Generally includes thickness measurement and near-surface flaw detection. HR series have less sensitivity and the GP or C series with -6db frequency bandwidth of 50-100% range.

*C Series – Composite (Piezocomposite) series of transducers have superior sensitivity and penetration, especially in highly-attenuative materials. C Series have both higher resolution, sensitivity, and have wide bandwidth (60-120% at -6db) due to the lower acoustic impedance of the material. They couple more efficiently into plastic wedges, delay lines, and water.