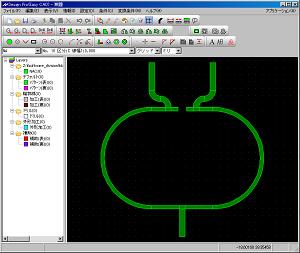

EASY CAD

PCB Layout Software, Easy to Use

Simple for the beginner and useful tool to designing high-frequency pattern

Simple Operation for Creating Double-Sided Board

After setting the line width and pad size, you can easily create a single or double-sided board.

Simply double-click to switch top to bottom layer and generate pad for through hole.

Enter Dimension at Keyboard

It is useful function for designing high-frequency pattern to enter dimension at keyboard.

For Anyone Familiar with Mechanical CAD Software

EASY CAD have the valious editing commands popular in mechanical CAD software:

extend line, parallel, corner round, corner bevel, move/copy (straight, rotation, mirror), offset, hatch and so on.

Milling Line Creation

The milling lines for the cutter are created automatically while applying a 1/2 offset for the milling cutter channel width around the outside of the completed pattern. If additional milling lines are created, unwanted copper lamination can be removed.

Information

The X,Y coordinates of elements and the distance between the centers of two elements or the distance between their adjacent edges are displayed.

Truetype Font Support

You can enjoy to mill a variety of Truetype Fonts.

Operational Environments

Minimum Operating System

Design View

Software that displays images with the camera.

Operational Environments

Minimum Operating System

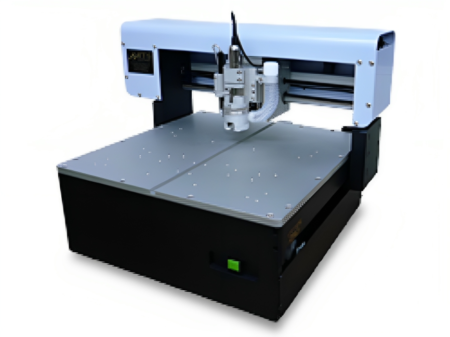

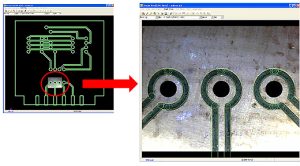

Check the result with the data pattern on the monitor

With our new “Overlay Function”, no extra work is needed to check the result with magnifier (loupe); it will overlay the resulted milling path and data pattern on monitor, easy to use and very helpful function for making RF boards.

Overlaid image of pattern and the board

Measures the distance from fiducial point accurately

Adjusting and aligning position is not a problem using the camera for processing double-sided boards or additional

process on a completed board. Having the camera image displayed on the monitor, it gives the user an easier time and confidence that it’s in a correct position.

Image of alignment to fabricate double-sided board

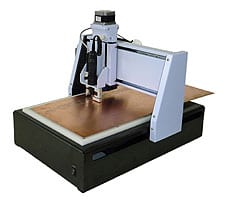

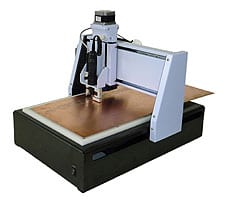

Fabricate boards larger than the working area

(Note: Manual Tool Change machine only)

In the past, the working area was limited just its working area for any prototyping machine. Having the camera, it opened up opportunity to process 2,000mm boards with our “segmented fabrication”.

Milling the front side of large PCB

Slide the board, milling the back side of large PCB

It will fabricate part of the data, then slide the board and use the camera to align and adjust for further fabrication.