SHM.Blade

SHM.Blade® – Intelligent System for the Detection of Structural Damage and Aerodynamic Imbalances on Rotor Blades

Rotor blades of wind turbines are exposed to extreme environmental conditions and high dynamic stresses. At the same time they have a decisive influence on the energy yield and thus on the economic efficiency of a wind turbine. Incipient damage must be detected at the earliest stage possible and distinguished from normal environmental and operational influences. Severe damage can be prevented by the repair measures, which are comparatively inexpensive at this early stage. Downtimes due to damage that is not detected or detected too late are avoided and the energy yield is increased. Periodic inspections are not sufficient for an early detection of damage. Continuous monitoring ensures a higher level of safety.

SHM.Blade for the detection of structural changes on rotor blades

SHM.Blade for the detection of structural damage

SHM.Blade is a tried and tested system, certified by DNV GL, that can detect structural damage on rotor blades at an early stage. For this purpose, a reference condition is used which is determined individually for each rotor blade, fully automatically, immediately after the activation of SHM.Blade. The determination of the reference condition is a blade-specific learning phase which ensures the system’s high sensitivity to damage – despite the mass and stiffness tolerances caused during production. When the learning phase is completed, the system continuously calculates condition indicators, which provide information on the current condition of the blade at any given time. By means of a two-level warning and alarm concept, the wind turbine control can react and subsequent damage can be avoided.

SHM.Blade for the detection of aerodynamic imbalances

Nearly 50 percent of all wind turbines have inadequately balanced rotors. In at least 30 percent of all cases, this is due to aerodynamic imbalance. This results in stronger vibrations, which lead to higher loads and thus to an increase in the consumed lifetime of the drive train, rotor blades, tower and foundation. The aerodynamic efficiency and thus also the generated electrical power of the wind turbine are therefore reduced. In addition, increased noise emissions can occur.

With the help of the imbalance indicator calculated by SHM.Blade, aerodynamic imbalances can be detected early and precisely. This ensures a vibration-optimized and component-protecting operation. A reduction in output is avoided and the risk of a shutdown of the turbine is reduced. The integrated pitch angle monitoring also allows for a lifetime extension of the drive train components and support structures.

Structural Health Monitoring.Blade Brochure

Structural Health Monitoring.Blade Certificate

SHM.Tower

SHM.Tower® – Intelligent and Certified System for Monitoring Tower Vibrations and Maximizing Lifetime Extension

Vibration monitoring enables proactive optimization

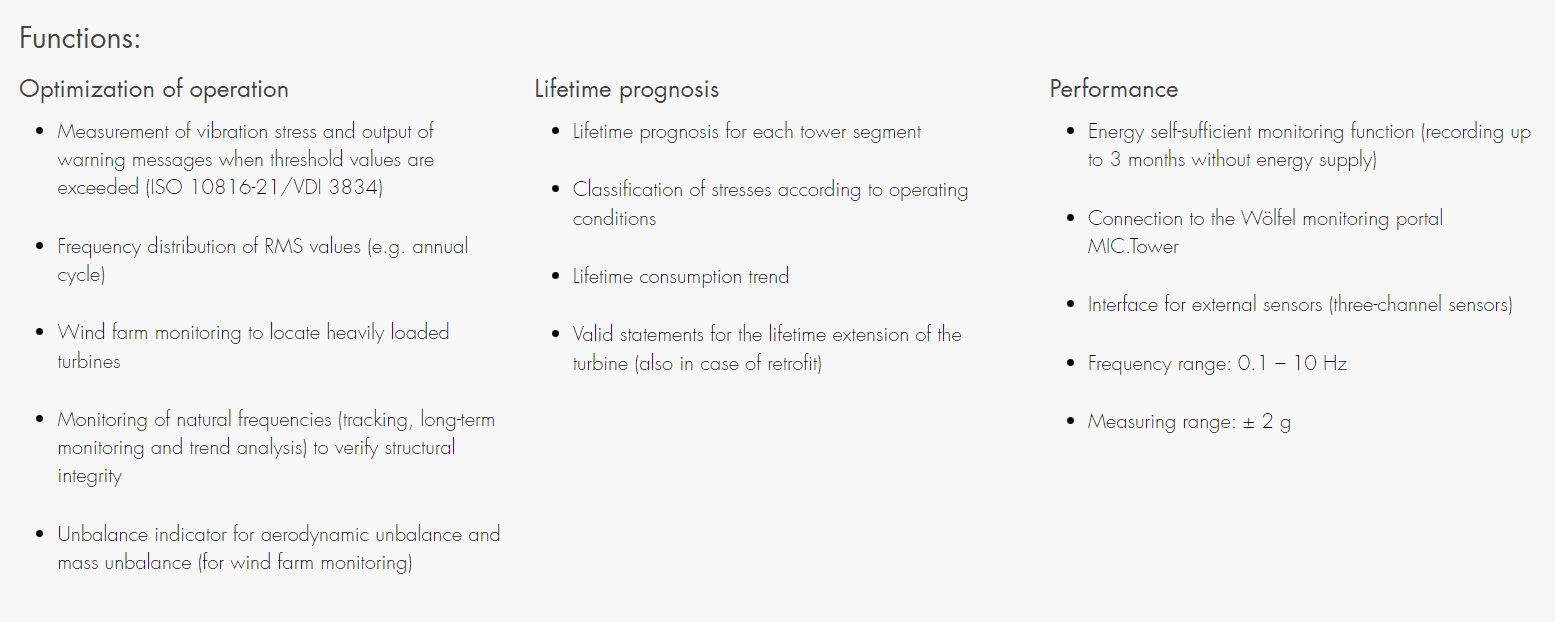

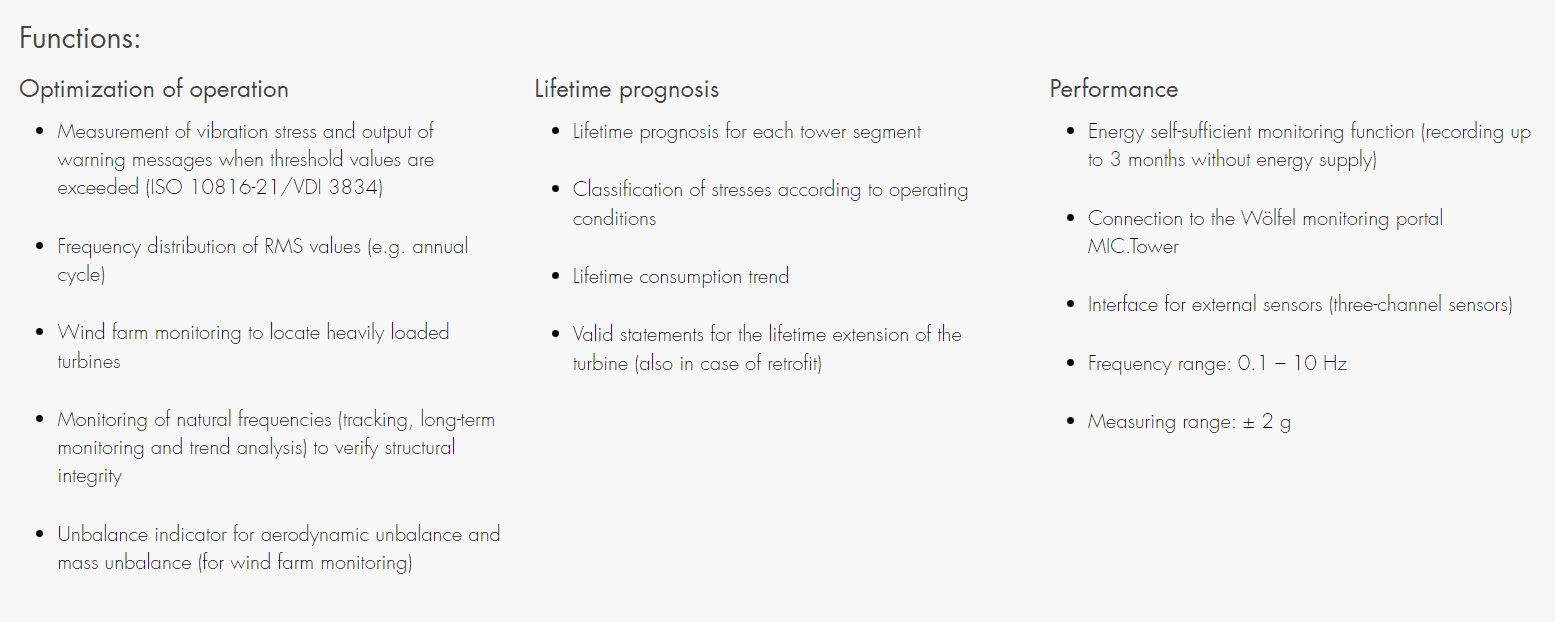

Depending on the location and mode of operation of a wind turbine (WTG), the vibration stress – especially on the tower – varies greatly. The monitoring system SHM.Tower records these stresses via an integrated sensor. Due to the permanent comparison of the current RMS-values with the applicable standards – e.g. ISO 10816-21 and VDI 3834 – the condition of the turbine is always visible at first glance. Turbine settings and operating mode can be continuously and proactively optimized. The system issues warning messages if predefined threshold values are exceeded. WTGs with excessive loads are thus immediately identified and countermeasures can be initiated.

Reliable lifetime prognosis and optimized lifetime extension

Wind turbines are usually designed for a lifetime of 20 years. However, at the end of this design lifetime there is often a great potential for further operation. The decision on this is made within the scope of a lifetime extension report. So far, these are usually based on historical operating and wind data as well as turbulence reports. However, due to conservative load assumptions and insufficient consideration of the wind direction – and thus the distribution of lifetime consumption across the tower cross-section – the overall potential for a lifetime extension for as long as possible is often significantly underestimated.

SHM.Tower calculates the loads that actually occur and are distributed over the tower cross-section based on the accelerations measured in the tower and thus enables an exact statement to be made about the actual lifetime consumption. Even critical extreme conditions are directly recorded. Thus, the lifetime prognosis is no longer based on assumptions alone. The lifetime extension can be maximized and the entire yield potential can be tapped.

Vibration monitoring system SHM.Tower

Use from the start or as retrofit

Sensors and electronics of SHM.Tower are built into a compact housing and allow for an easy installation in the tower head of the turbine. If the system is used right from the start, the operating status and the consumed lifetime are precisely recorded throughout all phases of use – thanks to the energy-autonomous mode even during construction and in the event of power failures. However, even if SHM.Tower is retrofitted, the system provides significantly improved lifetime assessments compared to conventional methods – even though the vibrations of the first years of operation are not recorded. Extrapolations enable the assessment over the entire service life.

After the initial lifetime extension report, you can optimally accompany the remaining service life of your WTG by continuously monitoring the vibration levels and tower loads.

SHM.Tower was already certified as a Condition Monitoring System by WindGuard Certification GmbH in 2019. In 2020, the implemented load reconstruction methodology was also successfully assessed. It could be proven that SHM.Tower enables load measurement with a very high accuracy and is therefore very well suited for use in the context of lifetime extension reports:

„Now that it was shown that the vibration profiles recorded with SHM.Tower are a very good representation of the system dynamics relevant for fatigue, there are indeed valuable possibilities for assessing the lifetime extension of modern WTGs. On the one hand, the DELs derived from vibrations can be used to validate and optimize the dynamic calculation model in order to minimize conservative safety factors. On the other hand, the measured load distribution in the tower cross section can be used to reduce the determined damage to the foundation and tower. In real terms, this results in a significant lifetime extension beyond the usual service life horizon without any loss of forecasting reliability. We have proven this in the assessment procedure.“

Frank Weise, Managing Director of WindGuard Certification GmbH

Structural Health Monitoring.Tower and Structural Health Monitoring.Foundation Brochure

Structural Health Monitoring.Tower Certificate

SHM.Foundation

SHM.Foundation® individual

Fully configurable system for the comprehensive monitoring of building ground, foundation and supporting structure in the offshore area

With the SHM.Foundation individual monitoring system, the structural behaviour of your wind turbines and substations can be recorded, tracked and evaluated in compliance with the guidelines. The focus is on the detailed analysis of maximum and fatigue loads, the acting wind and wave loads, the structural condition and the resulting remaining lifetime, as well as the detection of corrosion and scouring.

The configuration of SHM.Foundation individual

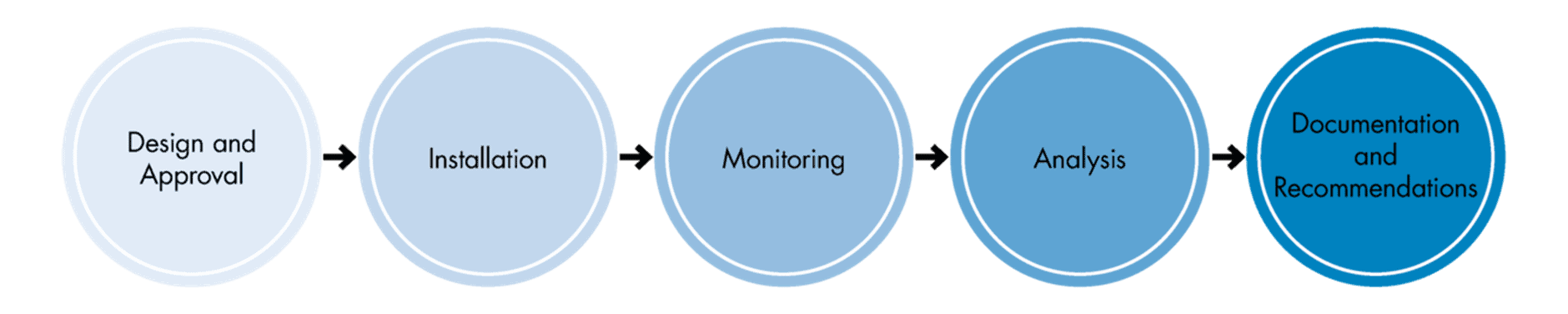

Both the necessary hardware and the software for data analysis are individually configured to meet your project requirements. On the basis of our many years of experience, we advise you on the way to the system configuration that is individually suitable for you.

However, we do not only accompany you during conception, installation and commissioning, but throughout the entire monitoring process. Within the scope of signal analysis, we extract the information that is essential for you, compare the recorded stresses with design assumptions, calculate the lifetime consumption, prepare reports for approval authorities and identify optimization potential.

Reduction of visual inspections and lifetime extension

Without a suitable monitoring system, damage can only be detected and monitored by regular visual inspections. These are usually complex and expensive. The monitoring of variables such as displacements, deformations, component stresses or frequencies is therefore unanimously recommended. In numerous offshore projects, however, only the monitoring of ten percent of all turbines has been established so far.

Since each wind turbine has individual characteristics and damage, we take a more comprehensive approach and recommend that all turbines in a wind farm be equipped with a system for monitoring the tower and foundation structure. In offshore wind farms, we generally equip ten percent of the turbines with the comprehensive SHM.Foundation individual system and 90 percent of the turbines with the cost-effective standard SHM.Foundation system. This combination makes it possible to switch from the previously used time-based inspections to condition-based inspection concepts.

Comprehensive monitoring is also useful for onshore wind farms. It enables operation to be optimized at all levels and thus reduces operating costs. An additional advantage is the exact statement about the total consumed lifetime. This means that the assessment of the continued operation of the plant is based on the fatigue loads that have actually occurred. In contrast to the evaluation with conventional methods, the entire potential for lifetime extension can be exploited.

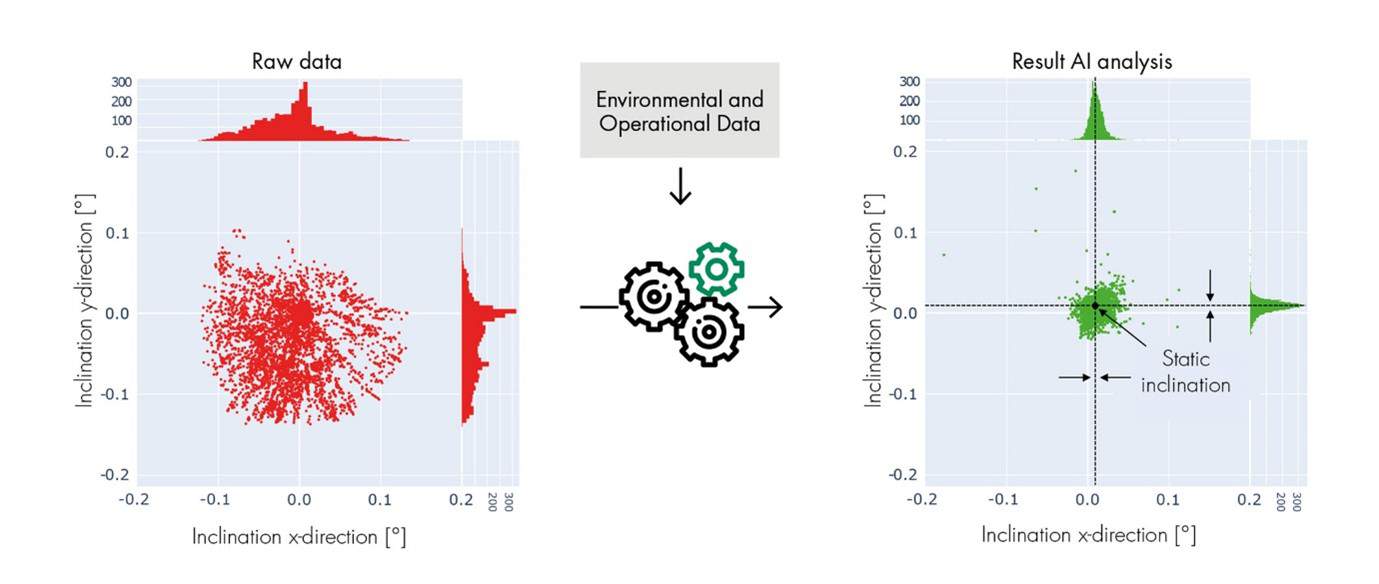

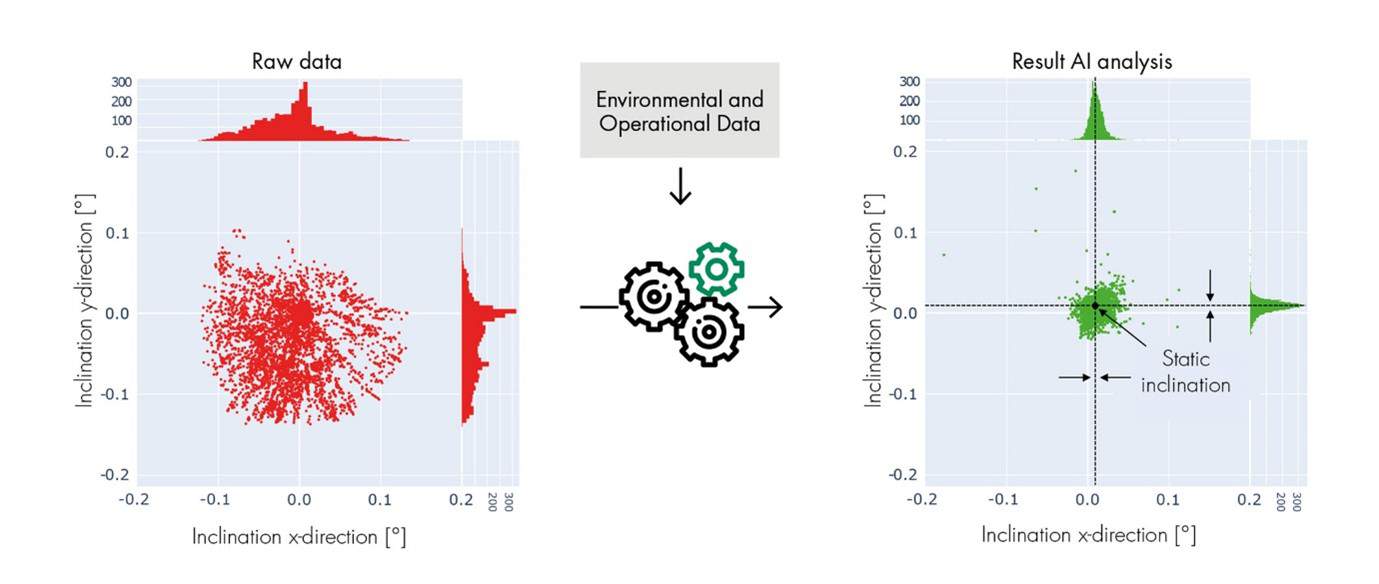

Artificial intelligence (AI) enables even more precise results

Correlation with EOC/SCADA data compensates for the dependence of the damage indicators on operating conditions. In addition, extended compensation with AI methods can significantly increase the accuracy.

Inclination without and with compensation of the operating conditions by AI

Structural Health Monitoring.Tower and Structural Health Monitoring.Foundation Brochure